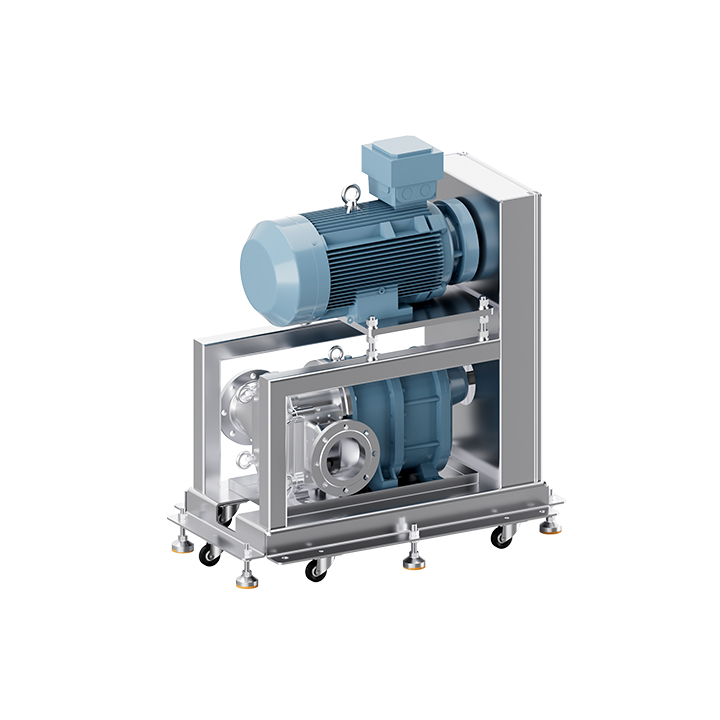

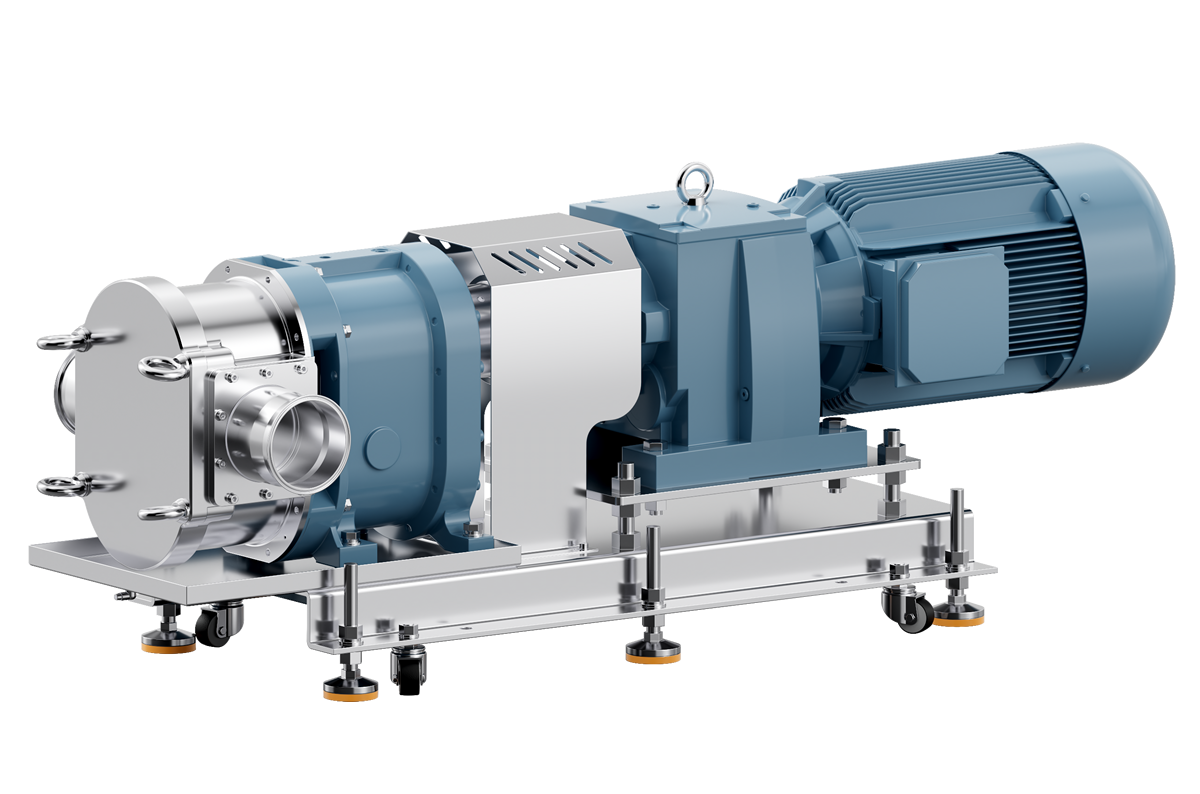

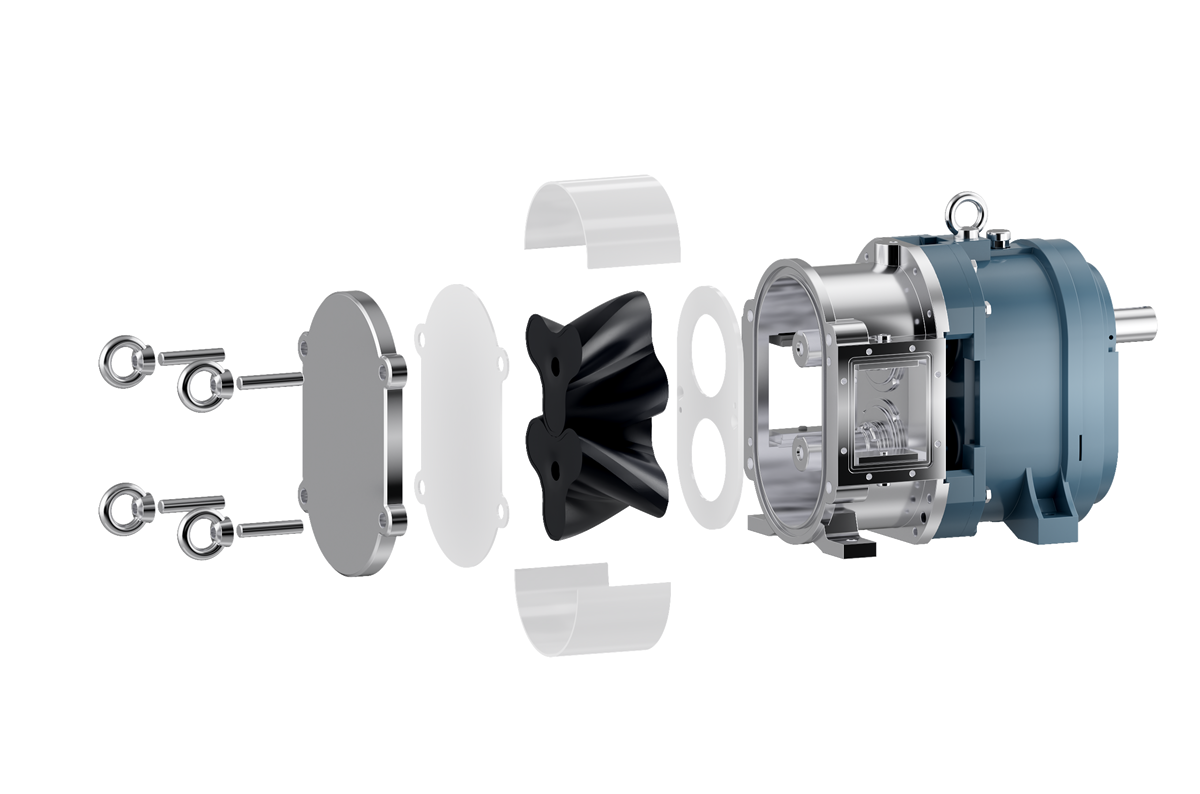

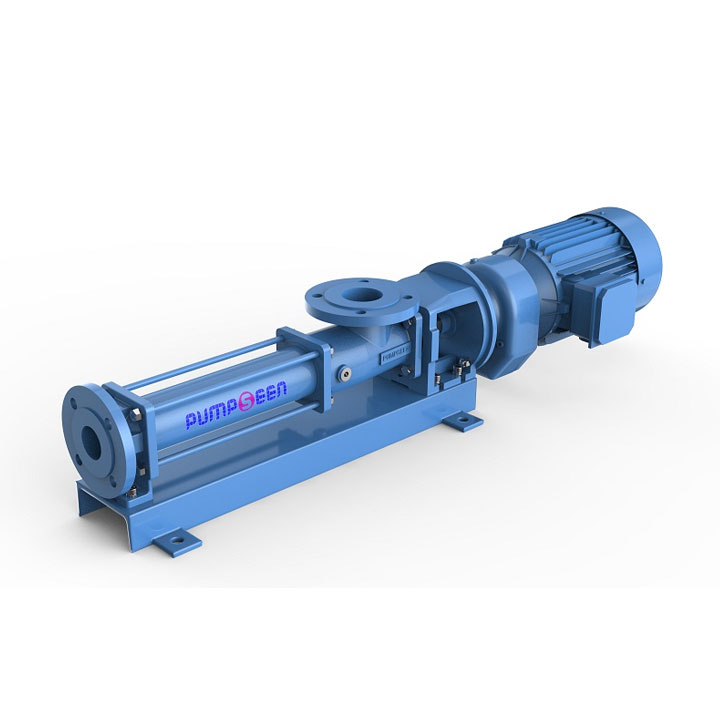

Ceramic rotor pump

Pumpseen ceramic rotor pump adopts ceramic-metal composite manufacturing technology to develop wear-resistant rotor pump, ceramic has high hardness, wear resistance, corrosion resistance and other characteristics, ceramic rotor pump adopts double-layer structure design of pump body, outer metal inner layer of ceramic, so the ceramic liner can protect the pump body and spare parts to a certain extent, extend the service life of the product, and in lithium battery and other industry applications, The ceramic does not contain copper and zinc elements, does not react with the medium, and protects the purity of the medium.相关案例

RecommendationsPumpseen sincerely invites you to visit the China World Expo

1661- 参数标题参数内容

- 参数标题参数内容

- 参数标题参数内容

The 25th China Global Expo will continue to be held in Shanghai New International Expo Center from April 18-20, 2024 with the exhibition scale of 200,000 square meters. While opening up the whole industrial chain solution of urban, industrial a…

Pumpseen sincerely invites you to visit and exchange China International Battery Technology Exhibition

1429- 参数标题参数内容

- 参数标题参数内容

- 参数标题参数内容

“China International Battery Technology Exchange/Exhibition (CIBF)” is an international professional technical exchange/exhibition of the battery industry sponsored by China Chemical and Physical Power Industry Association, and is one of the mo…

Pumpseen Pump industry successfully won the bid for the chemical industry with an annual output of 300,000 tons of polyurethane new materials gear pump procurement project

1692- 参数标题参数内容

- 参数标题参数内容

- 参数标题参数内容

Recently, Pumpseen Pump industry with reliable product quality, rich technical accumulation, a lot of practical experience and perfect service system, successfully won the bid for the chemical industry with an annual output of 300,000 tons of pol…

Pumpseen Pumps invites you to attend the 2024 CIPPE Beijing

1691- 参数标题参数内容

- 参数标题参数内容

- 参数标题参数内容

With the rapid development of the global energy industry, the field of petroleum and petrochemical technology and equipment is ushering in unprecedented opportunities. Pumpseen Pumps is always on the road of technological innovation and is comm…

loading…

已经是到最后一篇内容了!

相关推荐产品

RecommendationsInternal gear pump

- 产地中国-芜湖

- 品牌PUMPSEEN

Telephone number* Ø Exterior (end cover, shell, bracket) : cast iron, ductile iron, steel, stainless steel and other alloys.Ø Interior (rotor, idler) : cast iron, ductile iron, steel, har…

External gear pump

- 产地中国-芜湖

- 品牌PUMPSEEN

Telephone number* External gear pump About: Pumpseen external gear pumps are the solution for high pressure pumping Bearing brackets on both sides of the gear allow a differential pressure of 34bar-170bar Motor pump o…

Single screw pump

- 产地中国-芜湖

- 品牌PUMPSEEN

Telephone number* Pumpseen PNS series single screw pump is the universal pump type of Pumpseen. This series of pumps is suitable for most industries, used to transport a variety of viscosity ranges and different solids cont…

Metal rotor pump

- 产地中国-芜湖

- 品牌PUMPSEEN

Telephone number* Pumpseen Metal rotor pump rotor and pump housing are stainless steel design, internal smooth without dead Angle, can be cleaned in line. It can smoothly transport high-viscosity and high-corrosive media witho…

loading…

已经是到最后一篇内容了!

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd