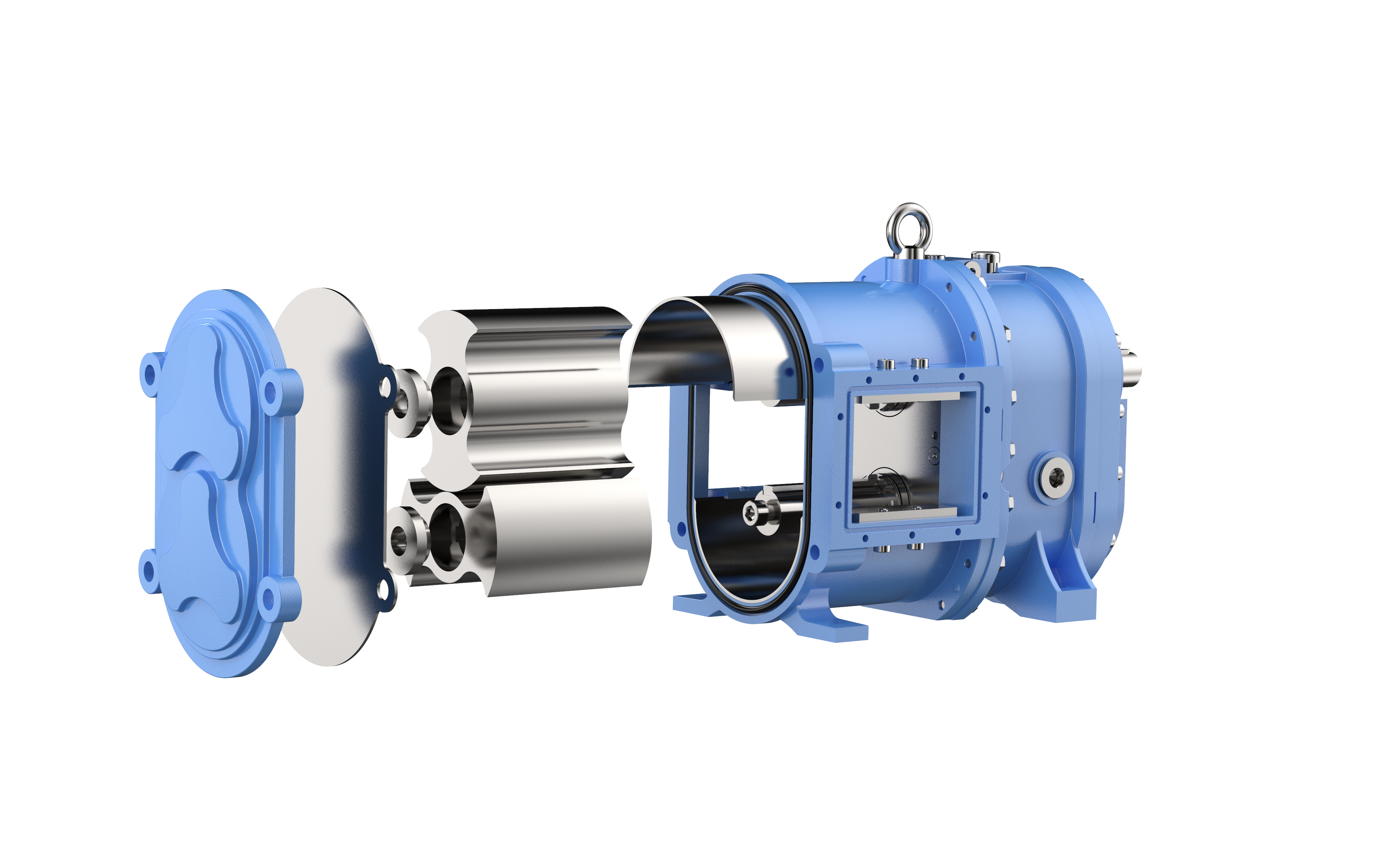

Metal rotor pump

Pumpseen Metal rotor pump rotor and pump housing are stainless steel design, internal smooth without dead Angle, can be cleaned in line. It can smoothly transport high-viscosity and high-corrosive media without pulsation. According to the corrosiveness, viscosity, wear, temperature and other characteristics of the medium, the rotor of different forms and materials can be selected to meet different process requirements within the range.相关案例

RecommendationsPumpseen sincerely invites you to visit the China World Expo

1725The 25th China Global Expo will continue to be held in Shanghai New International Expo Center from April 18-20, 2024 with the exhibition scale of 200,000 square meters. While opening up the whole industrial chain solution of urban, industrial a…

Pumpseen sincerely invites you to visit and exchange China International Battery Technology Exhibition

1506“China International Battery Technology Exchange/Exhibition (CIBF)” is an international professional technical exchange/exhibition of the battery industry sponsored by China Chemical and Physical Power Industry Association, and is one of the mo…

Pumpseen Pump industry successfully won the bid for the chemical industry with an annual output of 300,000 tons of polyurethane new materials gear pump procurement project

1787Recently, Pumpseen Pump industry with reliable product quality, rich technical accumulation, a lot of practical experience and perfect service system, successfully won the bid for the chemical industry with an annual output of 300,000 tons of pol…

Pumpseen Pumps invites you to attend the 2024 CIPPE Beijing

1754With the rapid development of the global energy industry, the field of petroleum and petrochemical technology and equipment is ushering in unprecedented opportunities. Pumpseen Pumps is always on the road of technological innovation and is comm…

loading…

已经是到最后一篇内容了!

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd