Pumpseen Pump, as a research and development, production and sales of fluid transport solutions provider, is committed to providing more efficient, more reliable, more environmentally friendly pumping solutions for the composite industry. It will participate in the International Composite Materials Exhibition held in Shanghai on September 12-14, 2023. This exhibition aims to showcase the latest composite technologies, applications and products, and we look forward to discussing with you the pumping technology in the field of composite materials.

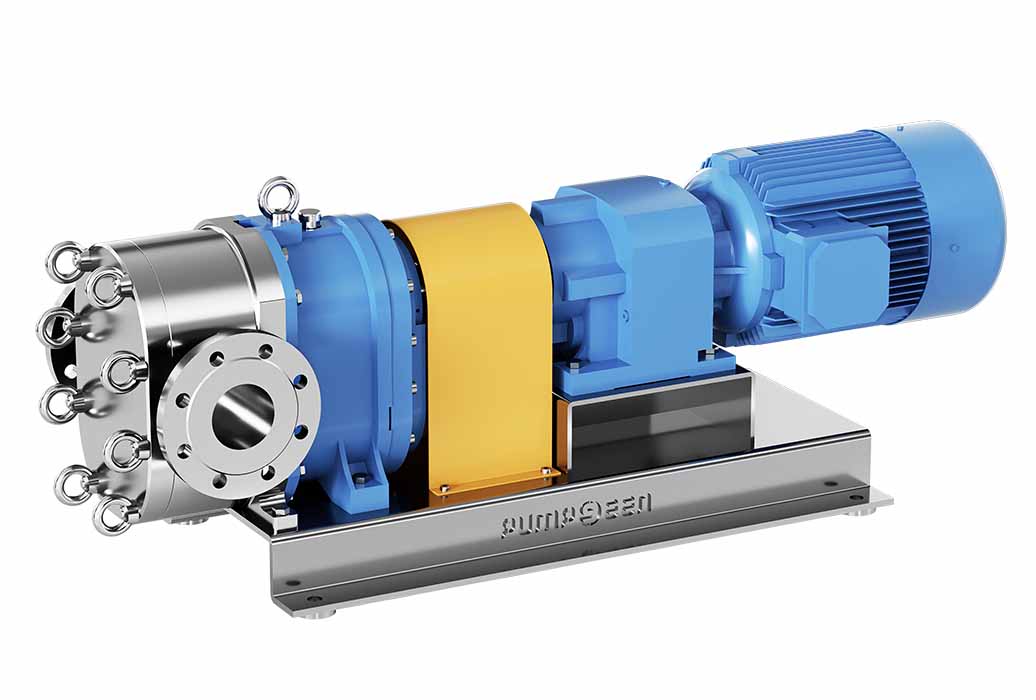

Pumpseen rotor pump has a wide range of applications in the composite material industry. With stable product quality and a wide range of application fields, it has established a good reputation in the fluid transportation industry. For a variety of complex transportation processes, Pumpseen rotor pumps can provide stable and efficient pumping effects, helping enterprises to improve production efficiency, reduce costs, and improve product quality.

The advantage of Pumpseen rotor pumps is that they are efficient, stable, environmentally friendly and easy to maintain when transporting high solid content and high viscosity media. At the same time, our team will provide a full range of technical support and after-sales service, different types of rotor pumps, materials, to meet the needs of different composite material production processes. In addition, we also provide customized services, according to the specific needs of customers and process requirements, customized suitable rotor pump products, to ensure that customers in the use of the experience.

Pumpseen rotor pump technical features:

· Flow range: 1-300m³/h

· Pressure range: 0-16bar

· Can transport solid particles up to 70mm in diameter

· Viscosity range: 1-1000000cps

· Temperature range: 0-200℃

· A variety of materials, forms of rotor can be selected to meet different process requirements

· Strong self-priming ability, no need for liquid infusion to start

· Symmetrical structure, reversible bidirectional operation, just change the driving rotation direction, you can change the direction of transmission

· It can be lined with wear-resistant metal liner to extend service life and reduce spare parts cost

· Convenient maintenance, no need to disassemble pipelines, reduce downtime and maintenance time and labor costs

· Diversified flange connection forms, flexible installation forms and pipeline connection forms

We look forward to working with you to explore innovations and developments in the field of composites to provide even stronger support for your business. Please visit Pumpseen booth, looking forward to your visit!

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd