Efficient and durable metal rotor pumps help the chemical industry upgrade

In the chemical industry, rotor pumps, as an important transportation equipment, can ensure the safe, stable and efficient transportation of various fluids in the production process. Among them, metal rotor pumps have received extensive attention for their excellent performance and durability.

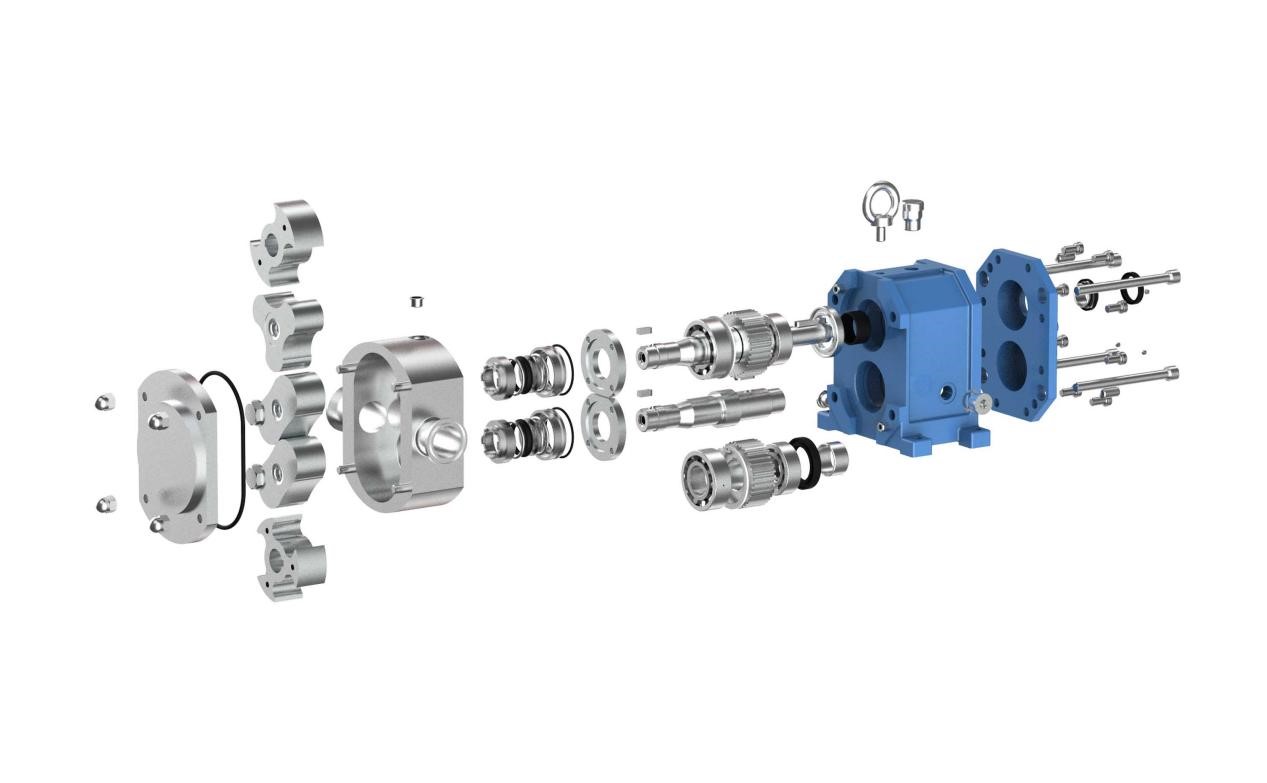

The metal rotor pump has a unique design for excellent sealing performance and efficient delivery. It uses a rotating rotor to form a series of sealed chambers in the pump chamber to transport the liquid from the inlet to the outlet. Design compact structure, smooth operation, rotor can choose 304, 316L, 2205 and other materials, can adapt to a variety of high viscosity, corrosive and wear liquid.

Metal rotor pumps also have the following outstanding advantages:

High efficiency: The transmission efficiency of the rotor pump is high, which can effectively reduce energy consumption and operating costs.

Stability: The sealing performance of the rotor pump is reliable, which can avoid leakage and pollution and ensure the stable operation of the production process.

Corrosion resistance: It is made of corrosion-resistant metal materials, which can resist the corrosion of various chemical media to ensure the long-term service life of the equipment.

Easy maintenance: quick-start pump cover, maintenance without disassembly of the pipeline can achieve rapid maintenance, rotor pump parts less, easy maintenance, reduce maintenance costs and downtime.

Strong adaptability: can adapt to different working environments and transportation requirements to ensure the stable operation of chemical production.

In the chemical industry, metal rotor pumps are widely used in various occasions, such as acid and base transportation, dye processing, pesticide production, petrochemical and other fields. With their excellent performance and durability, metal rotor pumps have become the chemical industry’s choice.

Select high-quality metal rotor pump suppliers, able to provide a full range of technical support and after-sales service to ensure that the equipment in production

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd