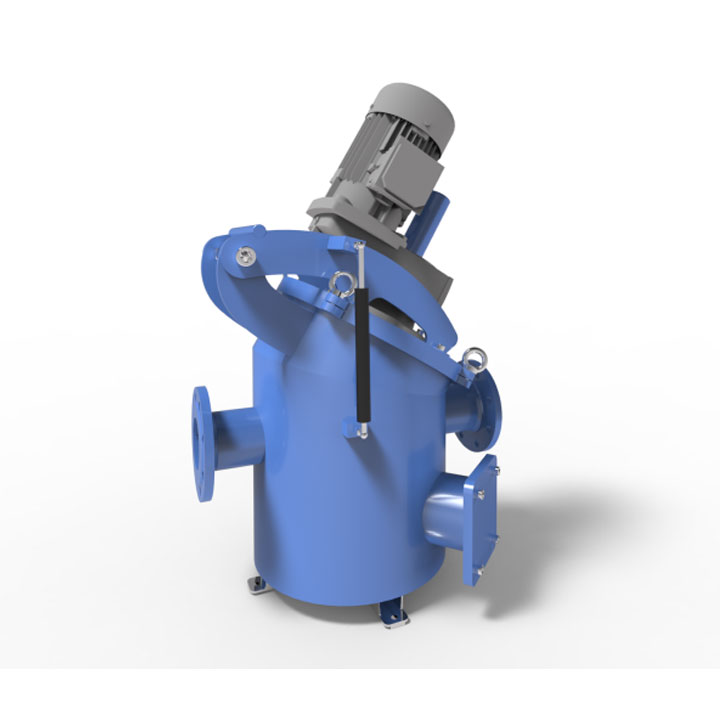

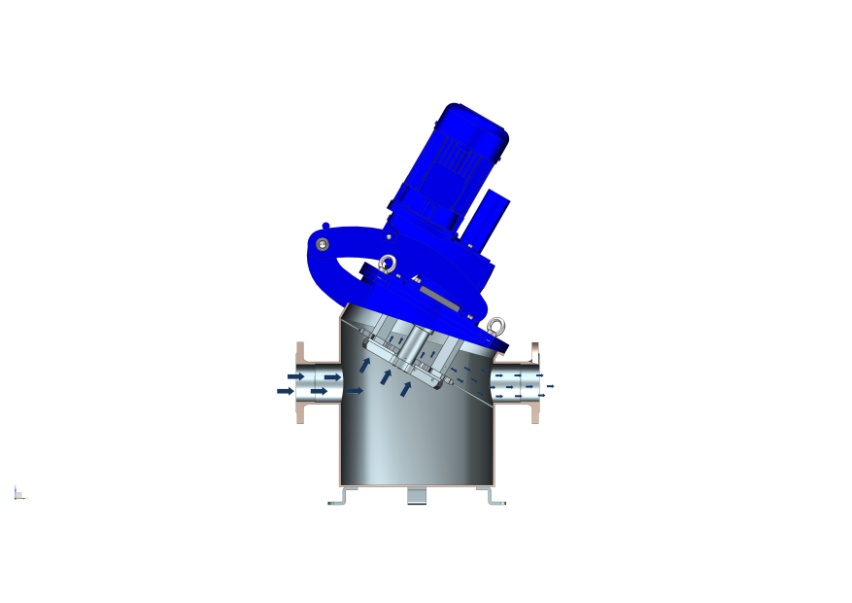

Cutter type cutting machine

Pumpseen cutter head crushers are used to break solid or fiber components in the medium, effectively protecting pumps and other process equipment such as centrifuges and filter presses, improving system reliability and extending system life.相关案例

Recommendationsloading…

已经是到最后一篇内容了!

常见问题解答

- Daily inspection and maintenance

Screw pump is used to deal with the complex composition of the medium, the long-term will inevitably cause wear to the internal structure of the pump body, the base and the fastening bolts of the pump body may also loose, if you do not pay attention to the inspection may lead to the displacement of the pump body, resulting in pipeline rupture. Therefore, it is recommended that equipment users spend a few minutes before starting the equipment every day to observe the fastening bolts of the pump, gear box oil level, and disc wear, ensure that the machine is normal before starting, and carefully listen to whether the running sound is normal after starting, if the internal mechanism is damaged, it may cause abnormal sound.

- Make regular maintenance plan

It is usually recommended to carry out a more comprehensive inspection in three months to six months, and the specific time is determined according to the working environment and frequency of use. First, it is necessary to replace the oil of the gearbox, and clean the gearbox to ensure the lubricity of the screw pump. Pay special attention to the lubrication of the rolling bearing and transmission, and ensure that the rubber jacket of the coupling is intact without wear, and then check the aging and wear of a variety of vulnerable parts of the pump body, and replace the new parts as needed.

3. maintenance after a long time stop the pump

For the equipment that stops pumping for more than a week, it is recommended to pay attention to the lubricating oil or soapy water, and use the tool to pull a few circles to ensure sufficient lubrication before switching on the power supply. At the same time, remember to check the valve on the inlet and outlet pipe to ensure that it can work normally, and then use it normally after all aspects are confirmed.

The above is the basic introduction of how to maintain the screw pump, I believe you also have a clearer understanding of this, if you are interested in knowing more details, sustainable attention to the Papson pump industry.

Generally speaking, for a variety of liquids with different viscosity, CAM rotor pumps have advantages that other pumps cannot match. However, in liquid transportation, not only is the viscosity of the problem, and usually accompanied by high temperatures, high pressure and sometimes have corrosion, or with solid particles characteristics. Therefore, when using a cam-rotor pump, it is important to take into account the following provisions:

1, the flow rate of the liquid to be transported, the application range of the selected pump to the viscosity.

2, for the occasion of measurement requirements, the selected pump has good performance stability when the viscosity and other process conditions change.

3, the back pressure of the system, the pressure range of the selected pump.

4, suction performance, high viscosity suction performance.

5, high temperature resistance, corrosion resistance, etc.

6, the structure is simple, easy to disassemble, clean and repair.

- Own parameters

We need to determine our own parameters, such as the maximum sewage flow in the peak period, which can be determined by the number of drainage outlets, which can be calculated by our technical staff.

- Lift

We also need to consider the head, the lack of head will lead to the normal elimination of the ground medium, and even the phenomenon of the media backfilling; If the lift is too high, it will lead to the waste of subsequent resources. Generally speaking, the appropriate head is the vertical height of the bottom of the medium to the water pipe network, if you are not clear about the head you need, you can be measured by professionals on site.

- Types of sewage media

We also need to know the type of medium in order to choose a pump with which water inlet and rotor. If the sewage contains particulate matter, it is necessary to choose a grinding sewage lift pump; If the sewage contains fiber, the cutting type of sewage lifting pump should be selected; Of course, if it is a washing machine, hand washing tray and other sewage sources that will hardly produce impurities, Eddy machine recommends that you choose an ordinary rotor sewage pump, which is more conducive to cost savings.

Step 4 Dissipate heat

When the CAM rotor pump is running, the speed is very high, the heat will be very high, and the heat dissipation ability will become an important indicator to measure it, look at the material of the motor and the material of the motor housing; Look at the CAM rotor pump is outside the water tank, the general pump is better, and the general technical content of the pump in the water tank is not too high, and the heat dissipation will be much worse.

- Box material

General pollution CAM rotor pump box material is PP/PE/ABS,ABS corrosion resistance is higher, HDPE material is more suitable for large box sewage lifting pump, but try not to choose stainless steel welded box, because the vibration of the pump will lead to crack, water leakage at any time, late maintenance is very difficult.

- Service life

This is certainly the longer the better, because the replacement and maintenance is more troublesome, many began to buy some cheap pumps in order to save costs, a few years down the maintenance and replacement cost has exceeded the purchase of a more safe and stable CAM rotor pump product costs, so try to choose well-known sewage pump manufacturers more reliable.

- Maintenance difficulty

Mainly depends on the installation position of the pump, the general CAM rotor pump is easy to maintain outside the sewage lift pump box, because the maintenance does not need to open the box; Of course, the price of the external pump equipment is much higher than the built-in, because the performance of the external pump is excellent enough, and the manufacturing cost of the whole machine is also higher; At the same time, see whether the equipment has a backwash function, if it does not have a backwash function, it is recommended to choose carefully, otherwise it is very difficult to clean yourself later.

- After-sales service

Papson machine provides survey, design and selection services free of charge. 7×24 hours after-sales response, free application solutions.

相关推荐产品

Recommendationsloading…

已经是到最后一篇内容了!

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd