Rubber rotor pump

The Pumpseen rubber rotor pump is designed by a pair of rotors installed on two parallel axes and the pump cavity for no gap between the design, so as to form a small sealed cavity, through a pair of synchronous gears to drive the two rotors synchronous reverse rotation, resulting in continuous displacement of the volume, so that the medium filled in the cavity is constantly pushed from one end to the other end, to achieve the transmission of fluid media. The rotor is made of rubber, engineering plastics and other materials, which is suitable for conveying media with high solid content, high wear and high viscosity, and suitable for conveying media in various industries.Product introduction

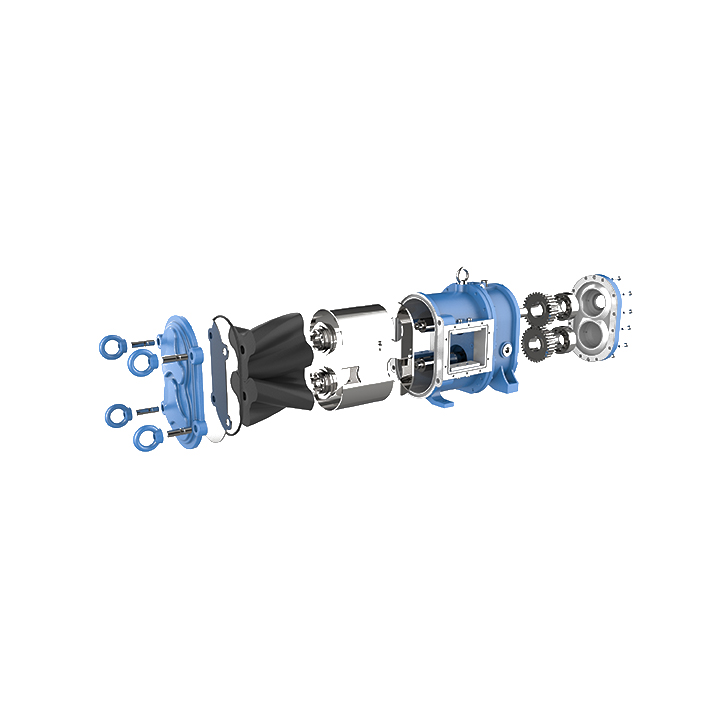

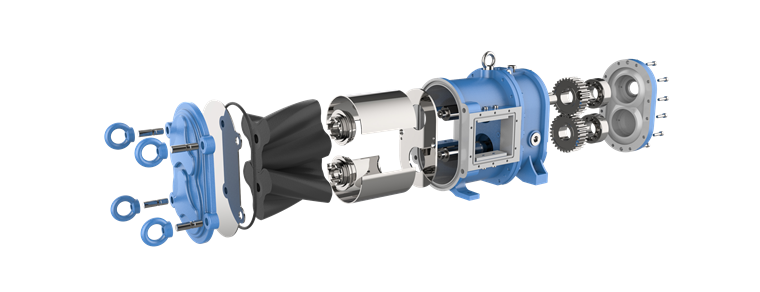

Product structure

Technical characteristics

Applied range

相关案例

Recommendationsloading…

已经是到最后一篇内容了!

相关推荐产品

Recommendationsloading…

已经是到最后一篇内容了!

Beijing Pumpseen Pump Industry Co., Ltd

Beijing Pumpseen Pump Industry Co., Ltd